Agglomeration Of Ore Fines XSM Rock Crusher .

Supply Agglomeration Of Ore Fines. Agglomeration Of Ore Fines ... XSM grinding mills vary from coarse grinding, ... Agglomeration Equipment ...

WhatsApp)

WhatsApp)

Supply Agglomeration Of Ore Fines. Agglomeration Of Ore Fines ... XSM grinding mills vary from coarse grinding, ... Agglomeration Equipment ...

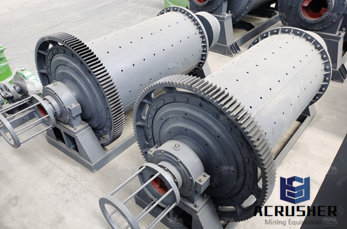

Ball mills are giant drums that are filled to between 30 and 40% of their volume with freely moving grinding media in this case balls. The diameter of the balls is ...

ball mill nano particle. Ball Mill ... Jet mills, Hosokawa Micron, Nano Particle Technology, Classifiers, Agglomeration, ...

Ball mills with ratios of 3 to 5 are ... during these processes can also result to agglomeration of particles and coating of grinding There are two types of ...

what is agglomeration mill ? Ball mill – Wikipedia, the free encyclopedia. A ball mill is a type of grinder used to grind materials into ...

Unlined steel, alumina and rubber lined ball mills are available. ... Dispersion, Emulsification, Homogenization, Deagglomeration Disintegration, ...

What Is Agglomeration Mill; What Is Agglomeration Mill. Agglomeration for Leaching Mining Technology | TechnoMine. ... agglomeration in ball mills ...

Home > Iron Ore News, Iron Ore Mining, > agglomeration of iron ores ball. Crushing Equipment; Grinding Equipment; ... Mineral Grinding Mills on .

On Feb 1, 2003 Nadine Le Bolay published: On agglomeration phenomena in ball mills: Application to the synthesis of composite materials

Improved Jc of MgB2 superconductor by ball milling using different ... In this paper, the effects of ball milling B powders using different media, such as ...

Additives are typically ground in either air swept vertical roller mills or horizontal ball mills, ... It is basically an agglomeration process achieved through ...

Nano Sizing Via Wet or Dry Grinding Nanosized particles are ... In deagglomeration, ... it is possible to achieve nanosized particles through jet mills operated ...

MILLS. CEMTEC mills are available in a wide variety of designs, sizes and power capacities. Each machine is tailormade according to the requirements of individual ...

Some devices, such as ball mills, are more suitable for coarse materials. These mills use "large" media, ranging in size from 20 mm in diameter ... agglomeration.

PARTICLE GROWTH AND AGGLOMERATION PROCESSES R. P. J. Sochon and Salman Particle Products Group, Department of Chemical and Process Engineering, ...

Supply Sintered Process Of Agglomeration Of Iron Ore. ... XSM grinding mills vary from coarse grinding, ... Ball Mill Raymond Mill Coarse Grinding Mill.

Aug 02, 2007· can anybody tell me how to design ball mill Help; Remember ... Ball Mills refer to ... does anyone know how to designor select lifter bars for a agglomeration .

Composites of poly(vinyl acetate) filled with calcium carbonate (CaCO 3) have been synthesized in a ball mill. The different steps in fragmentation and agglomeration ...

fritsch Ball Mills ... • Agglomeration phenomena avoided • Ergonomically positioned membrane keyboard IP65, splashproofed • Recyclable plastic housing

MultiStage Crushing versus AG/SAG ... • HPGR are more efficient than ball mills at low reduction ... deagglomeration, screening)

Grinding in Ball Mills: Modeling and Process Control ... Grinding in ball mills is an important technological ... and that no agglomeration processes take place ...

Liming Ball Mills; Toolgrinding The Tape Machine Tool; ... Design of a Crushing and Agglomeration Process for Manufacturing Bagasse Charcoal ...

agglomeration in ball millsartificial sand making machine tamilnadu,double head motor bench grinding machine,mineral iron ore daily price in malaysia,portable rock ...

Process plant depiction is for illustrative purposes only. YOUR SOURCE. EVERY STEP OF THE WAY. Sepro Mineral Systems Corp. knows mineral processing.

WhatsApp)

WhatsApp)